Directional drilling has become the innovative technique in diverse industries, allowing for accurate and effective installation of utilities, transport systems, and renewable energy structures. With the evolution of technology, comprehending the fundamentals of directional drilling becomes essential for industry workers and enthusiasts alike. This detailed guide aims to illuminate the intricacies of directional drilling, offering a beginner’s insight into its mechanics and uses, as well as emphasizing the best practices that can promote success in your endeavors.

Beginning at its inception to the cutting-edge innovations of today, directional drilling has seen significant evolution, permitting operators to navigate complex terrains and reduce environmental impact. look at this website will explore the various kinds of directional drilling, the key differences between perpendicular and parallel techniques, and the role this method holds in industries such as oil and gas, public services, and sustainable energy. If you are new to the field or wanting to improve your knowledge, our guide is set to give valuable insights into the positives, obstacles, and upcoming developments shaping the field of directional drilling.

Grasping Directional Boring

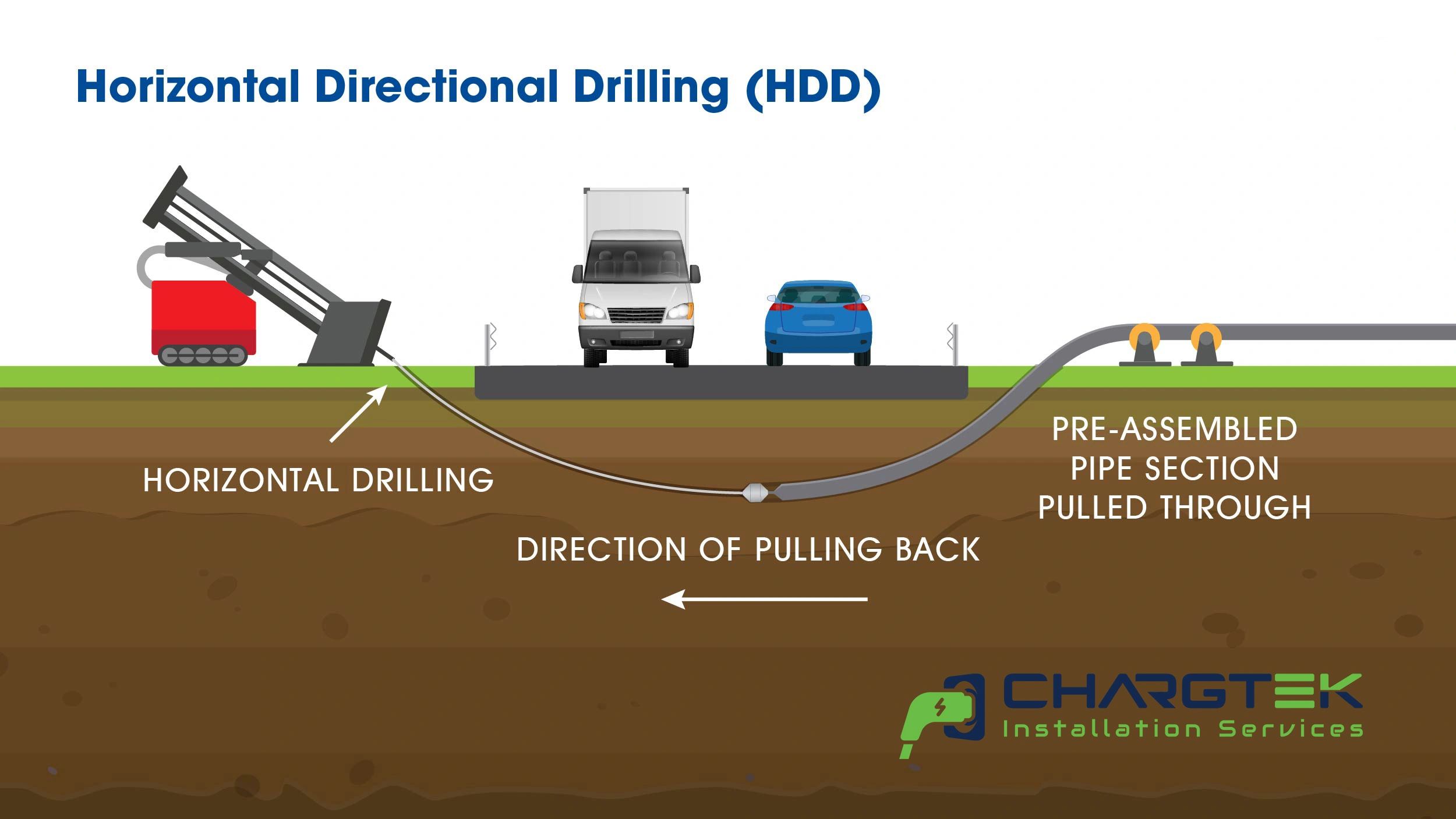

Directional drilling is a technique used in the boring industry that allows for the managed diversion of the drill bit from a vertical path. Unlike traditional vertical drilling, directional drilling enables operators to drill at angles and along curved trajectories, making it a versatile solution for various applications. This technique has revolutionized drilling by allowing access to deposits and resources that would otherwise be difficult or impossible to reach using conventional drilling techniques.

The method of directional drilling involves the use of specialized tools such as drill bits, mud motors, and steering tools. Operators plan and execute the drill path meticulously to ensure that the drill reaches its target efficiently and effectively. The mechanisms used in directional drilling has evolved considerably over the years, incorporating sophisticated monitoring systems and software that enhance precision and reduce the chances of issues during the drilling process.

Directional drilling not only boosts the effectiveness of resource extraction but also minimizes environmental impact. By reducing the need for various drilling sites and surface disruption, this technique aids preserve the local ecosystem. As industries persist to innovate and explore new applications for drilling, understanding the basics of directional drilling will become more important for both professionals and newcomers alike.

Advantages and Advantages

Horizontal drilling offers numerous benefits, making it a favored method for various projects. One of the key advantages is its ability to lessen surface disruption. Traditional drilling techniques often require extensive cleaning of land, which can damage ecosystems and create serious environmental challenges. In contrast, directional drilling enables for accurate bore paths that maneuver around barriers and diminish the overall extent of drilling operations. This is particularly beneficial in urban areas where minimizing disturbance is essential.

Another major benefit is the time and financial efficiency associated with directional drilling methods. Since this method permits for drilling several wells from a sole location, it reduces the need for additional drilling sites and the associated mobilization costs. The efficiency of directional drilling not only saves time during the installation but also speeds up project timelines significantly, leading to faster returns on capital. This is a compelling advantage for businesses looking to enhance their operational budgets.

Furthermore, directional drilling presents substantial environmental benefits. By lessening the amount of land affected and reducing the quantity of access roads needed, this approach diminishes the impact on natural habitats and local wildlife. It also allows companies to drill in sensitive areas, such as wetlands and along waterways, without causing significant ecological damage. As industries more and more prioritize sustainable practices, the adoption of directional drilling methods matches with goals for sustainable infrastructure growth.

Future Trends and Insights

The directional drilling appears to be set for significant advancements as the industry adopts new technologies and methodologies. Innovations such as live data analytics and artificial intelligence will enhance the accuracy and performance of drilling operations. By leveraging these technologies, companies can engage in informed decisions on drill paths and strategies, thus optimizing resource extraction while reducing costs and environmental impact.

Automated systems is likely to play a crucial role in the advancement of directional drilling. Automation can improve the precision of drilling techniques, minimizing human error and promoting safety. As the demand for more rapid and increasingly efficient drilling rises, automated drilling rigs and robotic systems are anticipated to become commonplace, streamlining operations and enhancing productivity across different fields, including oil and gas, utilities, and renewable energy.

In conclusion, the integration of advanced technologies, such as advanced software and sensor technology, will transform the way directional drilling projects are planned and executed. These tools enable immediate monitoring of drilling parameters, which can result in better management of resources and more rapid identification of potential issues. As the industry shifts to increasingly sustainable infrastructure, the ability to facilitate such initiatives through advanced directional drilling practices will be crucial for meeting the rising demands of urban development and environmental stewardship.